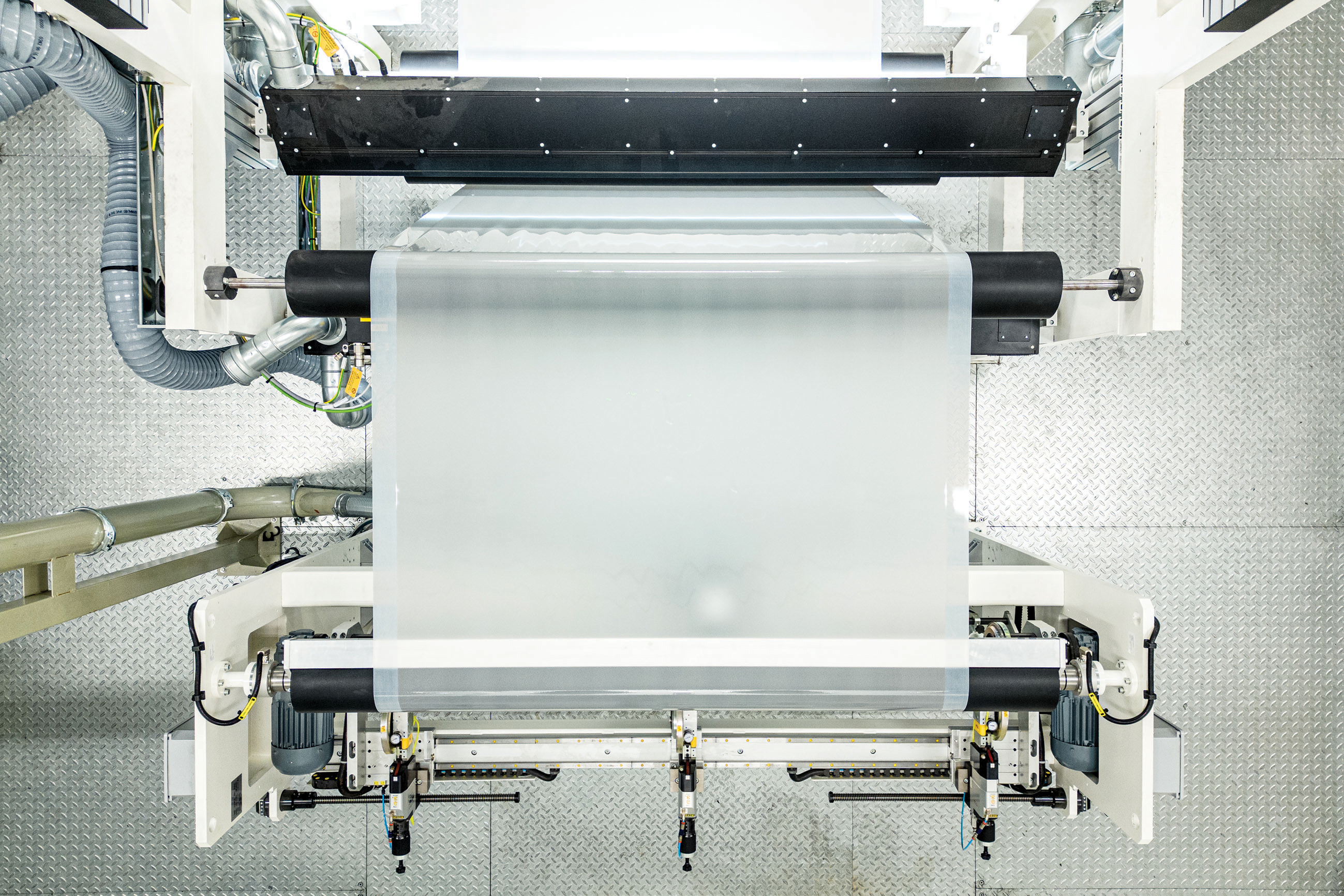

Coveme’s materials are tailored to guarantee performance and reliability in roll-to-roll (RTR) and sheet-to-sheet (STS) printing processes. The company works within a range of industries, including flexible circuitry, garment decoration, glucose sensor strip and furniture-panel manufacturing.

COVEME – ELEVATING PERFORMANCE OF POLYESTER FILM

Coveme’s surface-treatment technologies optimise the adhesion and functionality in materials. Its applications contribute to improved performance in a variety of areas. This critical factor ensures optimal ink bonding and holds importance in industries working with conductive, dielectric inks, adhesives and coatings.

Conductive inks require a precise and strong bond with the substrate to ensure conductivity and functionality of printed circuits. Coveme’s surface treatment – elevating the surface tension of the film – provides an excellent platform for these inks. This precision in bonding contributes to the integrity and durability in conductive traces.

Coveme’s heat-stabilisation processes are precisely designed to control residual shrinkage in materials. This ensures its maintenance of dimensional stability, under high-process temperature. The advancement is particularly important in the graphics and flexible-circuit industries.

In the graphics industry – where precise register keeping during the print process is paramount – Coveme’s heat-stabilised films offer a distinct advantage. By minimising residual shrinkage, the films enable accurate alignment of multiple layers during printing and curing, which results in high-quality graphics with excellent register keeping. This not only enhances the visual appeal of printed materials, but also streamlines the printing process, leading to increased efficiency and reduced waste.

In the flexible circuit industry, heat-stabilised materials ensure that the dimensional integrity of circuits is maintained. This is essential for the reliable performance of electronic devices, especially in applications with stringent size and space constraints.

“Coveme’s heat-stabilised materials ensure that the dimensional integrity of circuits is maintained”

Coveme’s coating technologies undergo meticulous engineering processes to impart transformative properties to materials, both in terms of functionality and aesthetics. For example, in the furniture industry, Coveme’s coatings transfer a layer that shields surfaces from environmental factors, abrasion and chemical exposure. Simultaneously, they contribute to the visual and haptic appeal of furniture, providing a durable and aesthetically pleasing finish.

The company’s commitment to innovation extends to hydrophilic characteristics in its films, adding a new dimension to material functionality. This involves modifying the film’s surface to exhibit hydrophilic properties, enabling precise control over liquid interactions. In this way, uniform wetting, promoting adhesion in medical applications and optimising liquid-based processes in IVD (In Vitro Diagnostic medical device) devices is ensured.

Coveme also provides release coatings – tailored for heat-transfer prints. The coatings offer a solution for applications such as textiles and industrial materials, where heat-transfer printing is prevalent.

Coveme films provide a print-receptive layer that simultaneously facilitates the smooth release of printed images onto the target surface during heat-transfer processes. Coveme’s expertise in coating technologies ensures that these release coatings not only enhance the touch and feel of heat-transfer printing, but also contribute to the longevity of the printed images. The result is a seamless, high-quality finish on various materials, meeting the rigorous standards of industries relying on these prints.

The company does not merely provide stand-alone products. It also offers integrated solutions that cater to the unique needs of each industry. Coveme’s research and development teams work closely with clients to understand their challenges and collaboratively develop customised solutions. This approach ensures that the business’s technologies seamlessly integrate into the unique workflows and demands of its diverse clientele.

“Coveme’s surface treatment provides an excellent platform for these inks”

Furthermore, Coveme places a strong emphasis on sustainability. The company is committed to reducing its environmental footprint. Additionally, it actively seeks and offers eco-friendly alternatives in its materials across its product lines and manufacturing processes. This commitment aligns with the growing global awareness of the need for sustainable practices in industry and is confirmed by Coveme’s various certifications such as ISO 14001, Oekotex and Ecovadis.

Coveme’s technologies set new standards in heat stabilisation, coating and surface treatment. They also play a crucial role in elevating performance in their fields of application. Through a combination of precision engineering, innovation and a commitment to sustainability, Coveme continues to be a leader in material science. As industries place a premium on performance, reliability and environmental responsibility, the business remains a strategic partner. Whether in the precision of flexible circuits, the vibrancy of graphic prints or the durability of furniture surfaces, Coveme’s technologies aim for excellence for the industries it serves.